The Tale of a Selfmade Entrepreneur

Our Chairman, Mr Maganbhai. J. Patel was born to a farmer living in a small village. He completed his schooling and graduation in a small town near Rajkot, India. He started off being a teacher in a government school before taking a big leap. With the help of his colleagues, he finally moved to “Rajkot”. In the 1960s, with the vision of achieving higher milestones and the mission of moving ahead to attain them, he put forth his first step in the world of ‘Engines Spares’. During those days, ‘Lister and Peter Engines’ were in demand globally so he started manufacturing them on small scale. Further, to capture a greater market area, he insisted on platting chrome on cylinder liners which turned out to be a huge success. With the help of this small yet effective step with his expertise and diversification helped him enrol “Biloree Cast (I) Pvt Ltd” on a large scale. Recognising the need of the hour for developing India, BCIPL expanded its body by setting up a large manufacturing facility that consisted of an in-house Foundry and Machining Shop. He guided with his full potential and elevated the company to become one of the most prestigious manufacturers of centrifugally casted cylinder liners in India.

Leadership Team

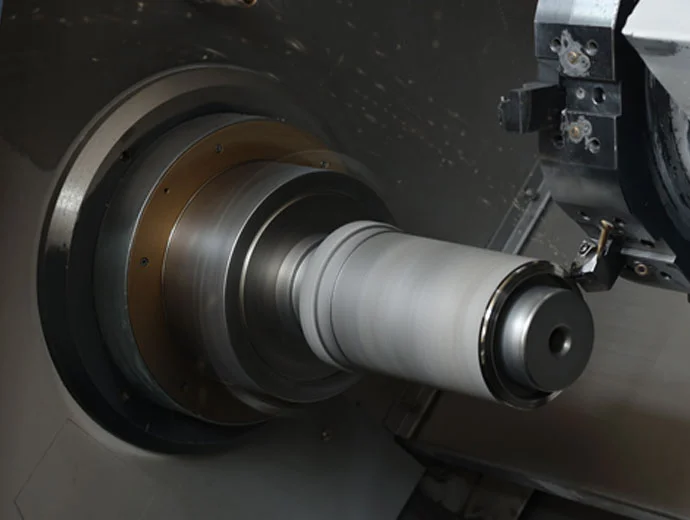

Manufacturing right quality product at right time is our focus and to fulfil that purpose, we expanded by setting up an in-house foundry and machining shop. Also, we do not believe in out-sourcing any components. The team is driven by the quest for continual improvement in all operations. So, our team works day and night to achieve the result-oriented target. We take pride with more than 350 employees in our team presently.

We aspire to cater to more markets and be the first choice of clientele for high-end and quality critical engine components. As a company, we are also moving towards a green future and our target is to run entirely on renewable energy by 2024.

Our mission stands to be a market leader, hence we invest heavily in Research and Development and Hi-Tech Machineries. Also, to continue innovating products required by the industries, thereby exceeding their expectations.

A Walk Through Our Milestones

Empowering Engines since 1969

Why Biloree

An Exceptional Engine’s Journey

If you are looking for a pathway to the right quality products at the right time with an eye to precision, ‘Biloree’ can be your go-to name!

View Infrastructure